Since 2021 innovating and contributing to a better world.

Recognized by the University of Minho for the innovative nature of the company in scientific and market terms, through the attribution of spin-off status, currently being part of the MSTN Group.

We develop natural, biodegradable and personalized

biomaterials in collaboration with our clients because we believe that each products should tell an unique history of circularity.

Biodegradable, Compostable or Recyclable

What are the differences?

Biodegradable

Materials that are decomposed in nature by the action of microorganisms, such as bacteria, fungi and algae.

Compostable

Materials that are decomposed into non-toxic components, such as water and carbon dioxide, yielding organic compounds (humus). Completely biological degradation process.

Recyclable

Materials that at the end of the life cycle of use of a given product can be reprocessed and used for the development of new products.

Why are bio-based materials the best choice?

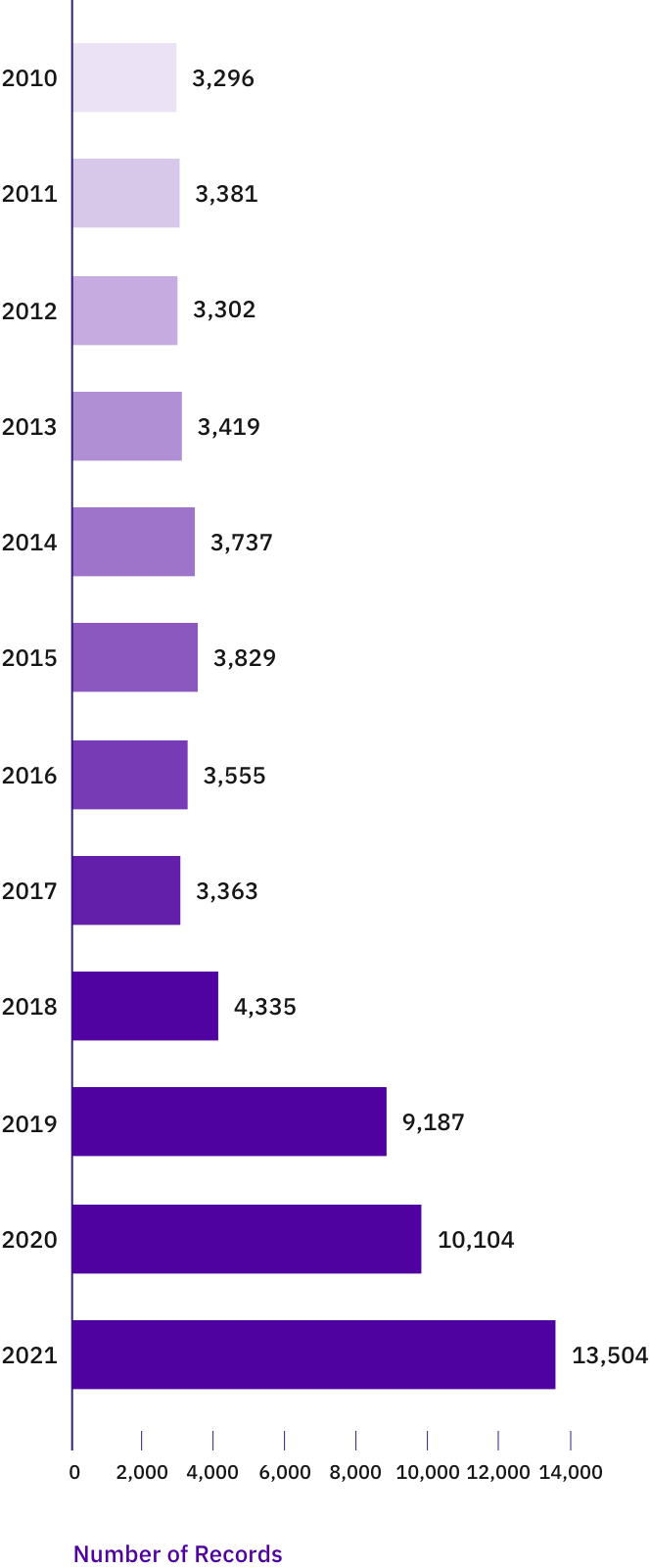

In addition to the Circular Economy policies that have largely dominated innovation agendas, the production, use and conservation of biological resources also aim at a sustainable economy strategy, as shown by the increasing numbers of records in recent years related to biomaterials:

Evolution of the use of biomaterials over the last 10 years

No Data Found

Evolution of the use of biomaterials over the last 10 years

Only 9% of plastic is recycled

According to recent estimates of plastics production and recycling, currently only 9% of the 400 million tonnes of plastics produced annually worldwide are recycled.

Use of by-products

The customization of our compoundings based on the valorization of by-products from different types of industries, in addition to reducing their impact on the environment, also allows you to create an emotional relationship related to your business area.

Need to reduce dependence on fossil resources

1970 was the last year in which the Overshoot Day was not reached, the day in each year when the consumption of natural resources made available by the Earth is depleted. Since then, the annual period of consumption of the ecological budget on credit has been increasing.

In 2022, that day was reached on the 28th of July.

65% of energy saving

The production of biomaterials, with characteristics similar to conventional plastics, can be up to 65% more energy efficient.

Why B4Logic?

Biodegradability

Biodegradable material at the end of its life cycle, reducing environmental impact compared to conventional plastics.

Customization

Possibility of developing compoundings according to your needs.

Scale

Possibility of developing small and large scales of raw material.

Circularity

Combined with the ease of customization, your compounding can allow the valorization of by-products associated with your business area.

Differentiation with B4Logic biomaterials

Having the opportunity to create unique packaging and products that tell the story of its origin and create more empathetic bonds with the final consumer through circular models.

Why B4Logic?

Biodegradability

Biodegradable material at the end of its life cycle, reducing environmental impact compared to conventional plastics.

Customization

Possibility of developing compoundings according to your needs.

Scale

Possibility of developing small and large scales of raw material.

Circularity

Combined with the ease of customization, your compounding can allow the valorization of by-products associated with your business area.

Differentiation with B4Logic biomaterials.

Having the opportunity to create unique packaging and products that tell the story of its origin and create more empathetic bonds with the final consumer through circular models.

What stories do your products tell?

Would you like to contact us directly?

info@b4logic.com

Contacts

Rua da, Zona Industrial de Vagos Lt. 100,

3840-385 Vagos

+351 234 799 120